Flexible and Hard – DLC-Coating of LASER-Structured Elastomers

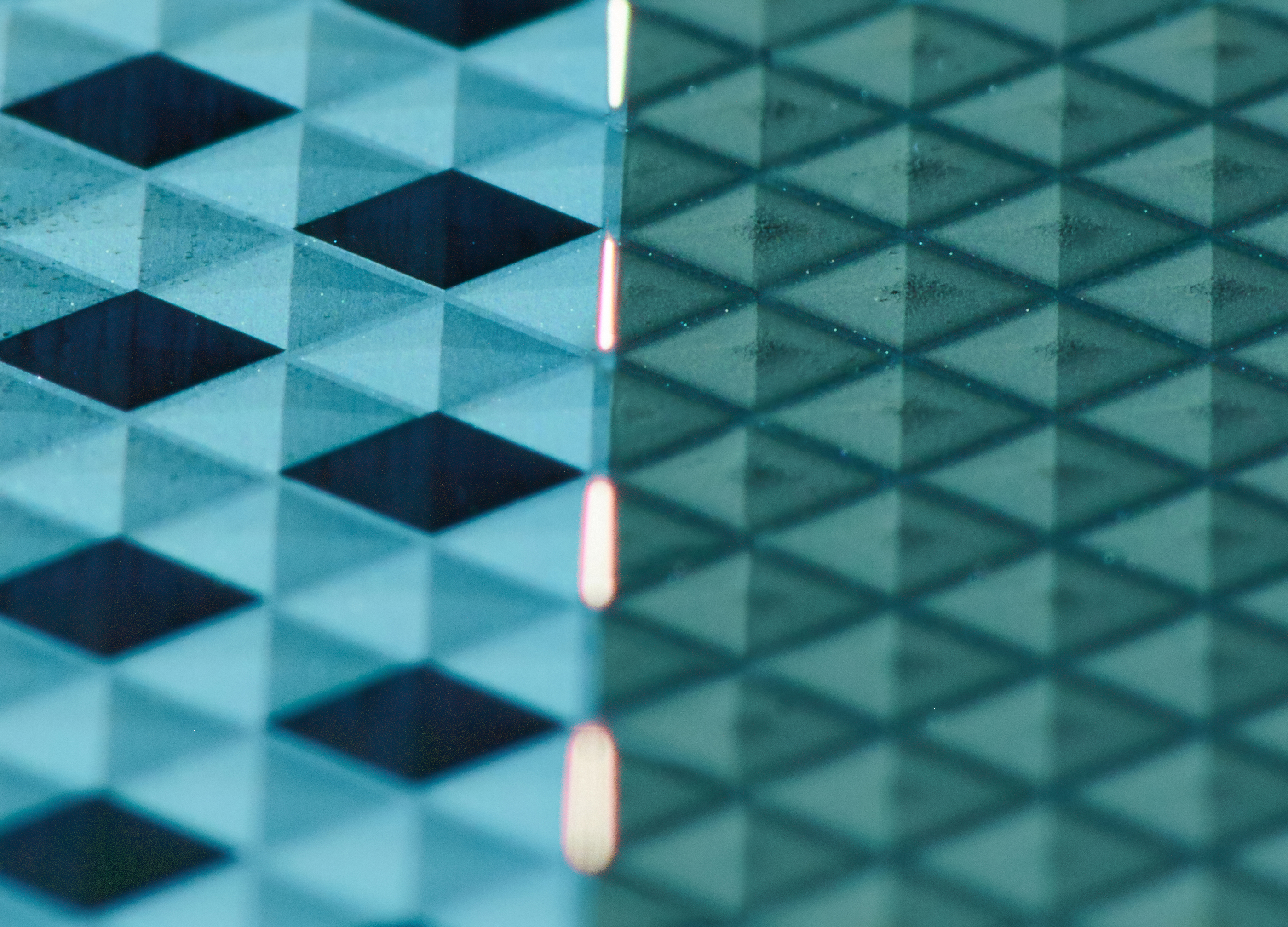

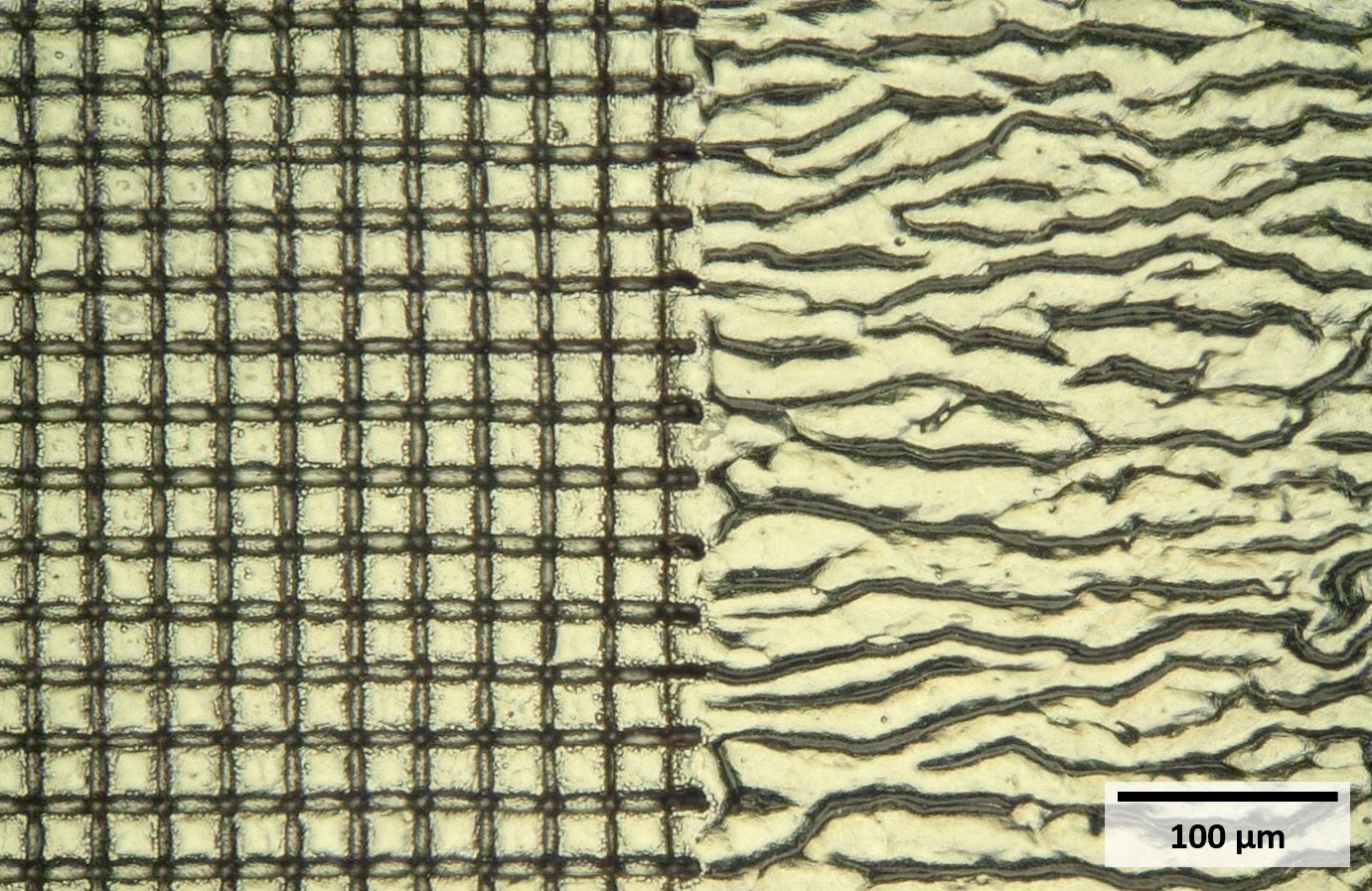

DLC-coatings show great potential in terms of friction reduction and life-time extension of highly stressed polymer components, such as bearings or elastomer seals. However, a distinct crack morphology is intrinsic to a DLC-coating on elastomer substrates. Due to the different ductility of polymer substrate and DLC coating, the coating is further fragmented under load up to delamination.

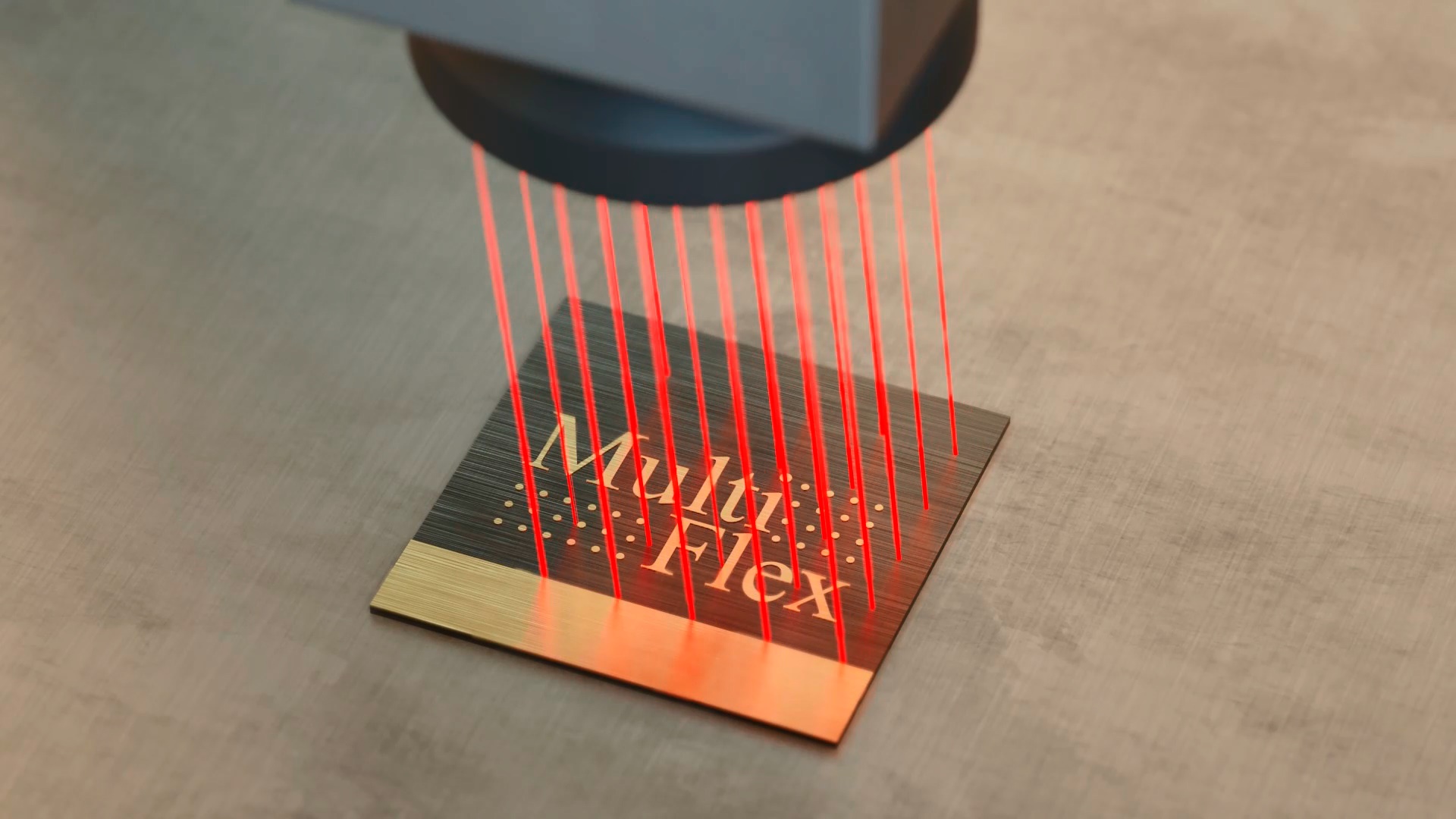

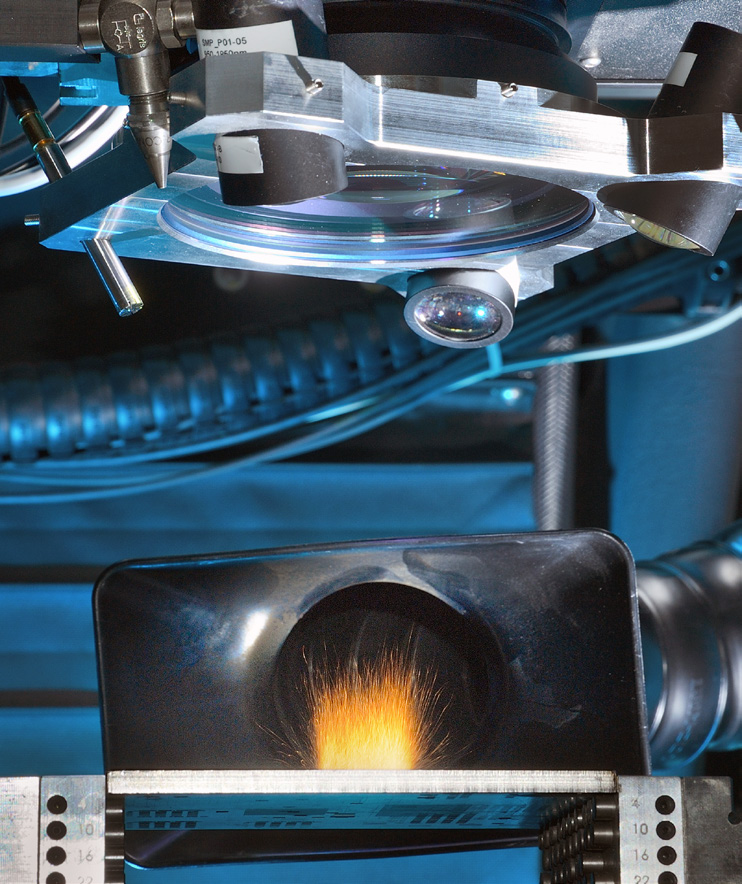

Fraunhofer ILT and Fraunhofer IWM achieved a predefined morphology of the DLC-coating by selectively laser-structuring of elastomer substrates. Further fragmentation can thus be avoided, achieving a higher resistance to delamination. The combination of laser structuring and DLC coating enables the production of low-friction and at the same time flexible, highly stressed elastomer components.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT